Continuing his recent series of blogs with us, WhichPLM Founder & CEO, Mark Harrop, shares his views on the future of PLM for fashion – both near term and longer term.

Over the last few years, WhichPLM has conducted a great deal of research into the broad subject of fashion technology. While our focus has always remained on PLM, our in-house analysts and expert contributors have also tackled topics like extended PLM, 3D, ERP, and – in our upcoming 6th Edition Report – the Internet of Things (IoT).

We see each of these as disruptive technologies that will – or already have – change the way the apparel industry looks at its product lifecycles, and the way it treats its data.

Today I want to remind our readers that far from replacing PLM, or making it obsolete, these technologies are actually securing its place at the heart of modern product design and development. While innovations like 3D and the IoT will undoubtedly influence the way PLM evolves in the future, PLM will in return provide them with both their context and their content – acting as a critical central repository for the data that’s going to define the way we create and the way we sell products to our customers.

In addition to its detailed look at the growth of 3D working in retail, footwear and apparel, and its world-class PLM market intelligence, our 5th Edition Report ended with a four-page special entitled The Future of PLM. This is a title we’ve used in previous years, but last October – when the 5th Edition was published – it assumed a new kind of importance. In that closing article, we wrote about how, in every industry, “one trend will loom larger than any other: connectivity”, and while we were introducing the concept of the IoT, we also raised the recurring topics of integration and big data.

In this short piece, I want to revisit what connectivity means for the future of PLM, and outline why I believe each new innovation in the E-PLM market only serves to reinforce its importance.

In last year’s closing article, we took great care to emphasise the difference between things being connected, and things being understood. The crucial distinction between the two is that connectivity is cheap and easy to add (although integrating solutions from different vendors is often neither) while understanding comes as the result of hard work, and an appreciation for just how far the footprint of PLM-driven connectivity extends into the modern enterprise.

To put it another way, as E-PLM continues to grow, the average brand or retailer will find themselves with significantly more data being generated on a daily basis than they do today. Each solution they buy and implement will have its own inputs and outputs, and will generate its own sets of data.

As I said earlier, creating information and pushing it into a network is one thing; making it available and intelligible where it matters is another, and that’s where the value lies.

And in a modern fashion business, “where it matters” can be anywhere in the extended, international supply chain. So getting a wider variety and a greater quantity of information to be known and understood by the people and processes that make up the concept-to-consumer cycle is, as I see it, one of the primary challenges facing the fashion industry.

I’m sure that, like me, you’ll have heard and maybe even used the phrase “digital transformation”. It’s certainly catchy, but you perhaps haven’t given it too much thought – I know many people who simply think of it as a handy way of referring to the steady introduction of new information technologies that will continue to open doors and provide new opportunities for brands, retailers and manufacturers.

I strongly believe, though, that now is the time to truly consider what it means – not only in light of the fact that businesses today are more digital than ever before, swimming in information (hence the popular term “big data”) but also to take account of what’s coming in the form of interconnected I.T. environments and the Internet of Things.

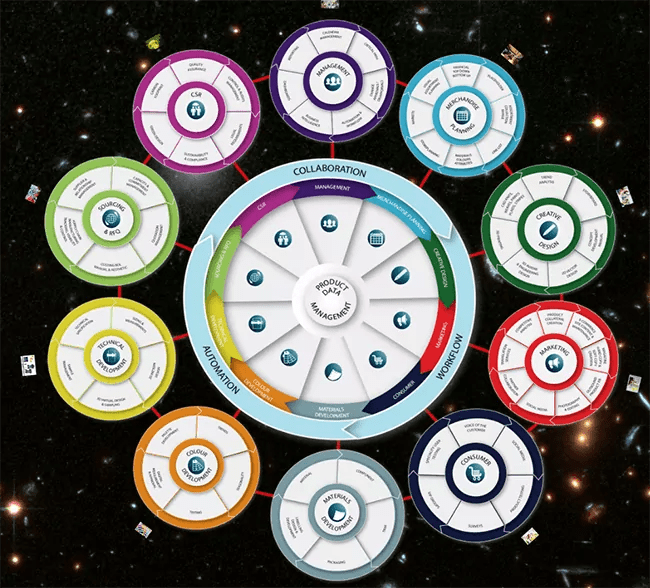

For the past few years I’ve been delivering a presentation I call “The PLM Universe”. You’ll notice an image taken from it on this page. I gave it that name because I found the best way to represent the 40+ processes that contribute to a typical product lifecycle to be as planets orbiting the central star of PLM. It’s an abstract way to think of things, but its aim is to get across just how many common activities, job roles, and disciplines rely on PLM (and on each other) to either push or pull their essential data.

The second part of the presentation then focuses on the introduction of new processes: something that, as I’ve said, is happening all the time, supported by the simultaneous introduction of new technologies. Needless to say, these each bring with them new digital information – data that sooner or later will need to find its way into the centre of the galaxy, and into PLM.

To provide some examples, the following are all relatively safe bets as processes and solutions that a modern fashion business may look to implement in the next few years:

- Trend analysis, driven by the voice of the consumer (VOC), trend services, and social media data analyse and reporting.

- Marketing and all of its sub-processes, requiring design teams, photographers, social media teams and other consumer-facing departments to share product data such as graphics, video, photography, measurements, manuals and which will be used to support Augmented Reality & Virtual Reality.

- Corporate Social Responsibility (CSR), which will rely on shared data between headquarters and supply chain partners, supporting legal requirements, transparency, audits etc.

- Enterprise 3D, delivering high-fidelity product images and models for use by designers, development teams, costing engineers, marketers and others.

- Management intelligence, with data from a huge range of different sources being used for visualisation, requiring the development of algorithms to support the massive quantity of Big Data held in PLM and ERP solutions.

- Mobile applications and, potentially, app-style expansions to PLM, supporting the hyperconnected modern employee, and extending the reach of PLM even further.

These are just a few examples of the many new processes that are being designed and implemented in a way that links them to today’s PLM solutions. Together they are combining to deliver real, exciting, quantifiable benefits for businesses of all shapes and sizes.

And remember: these are just a handful of examples of the ways in which the footprint of product data (and therefore PLM) has grown. Beyond them, we also expect to see a huge volume of new data feeds coming from dumb sensors / chips and more recognisable “smart” products – all of which will require collection and, crucially, understanding.

I believe there is no question that the right place to collect all of this data and make it understandable and accessible to systems, solutions, and human beings through the product lifecycle is in PLM. Today, the best PLM solutions are given equal importance to ERP, and seen as one of the core pillars of the modern enterprise. By making the fabled “single version of the truth” available to anyone, in an actionable, up-to-the-minute state, PLM will provide the backbone for the era of automation and dynamic, data-driven decision making.

We have now truly entered the world of “digital transformation” – a place where connectivity between “things”, “solutions” (called Machine to Machine, or M2M), and people (Machine to Human, or M2H) is revolutionising the way the concept to consumer universe looks. Rather than pushing and pulling between distant planets, we will be sharing continuous, round-the-clock collaboration and data flow across the entire extended supply chain. This, in turn, will lead to better products, as retailers, brands and manufactures embrace the cycle of consumer demand, creating a 360-degree process that thrives on contemporaneous information.

Although it remains important for retailers and brands to carefully consider the value of each of their integrations to and from PLM – particularly when we consider that a mid-sized brand may have up to 100 different such integrations to weigh up – experience has shown me that a good number of these solutions can potentially share valuable real-time or batched information with the main PLM backbone.

From now onwards, we need to think of “digital transformation” as a way of referring to all the different processes, products and people that need to come together, through technology, to complete the transactional and non-transactional halves of the concept-to-consumer cycle. This means PLM, 3D, E-PLM, the IoT, ERP and any other solutions that are added to the mix over time.

There is no single platform and no single answer, but I remain committed to the belief that PLM has a vital, central part to play in the future of fashion.

*The image in the left-hand column of this article is the sole property of WhichPLM.