In this topical blog, our founder and MD, Mark Harrop, shines a light on how today’s modern PLM solutions can help companies to reduce their negative impact on the environment.

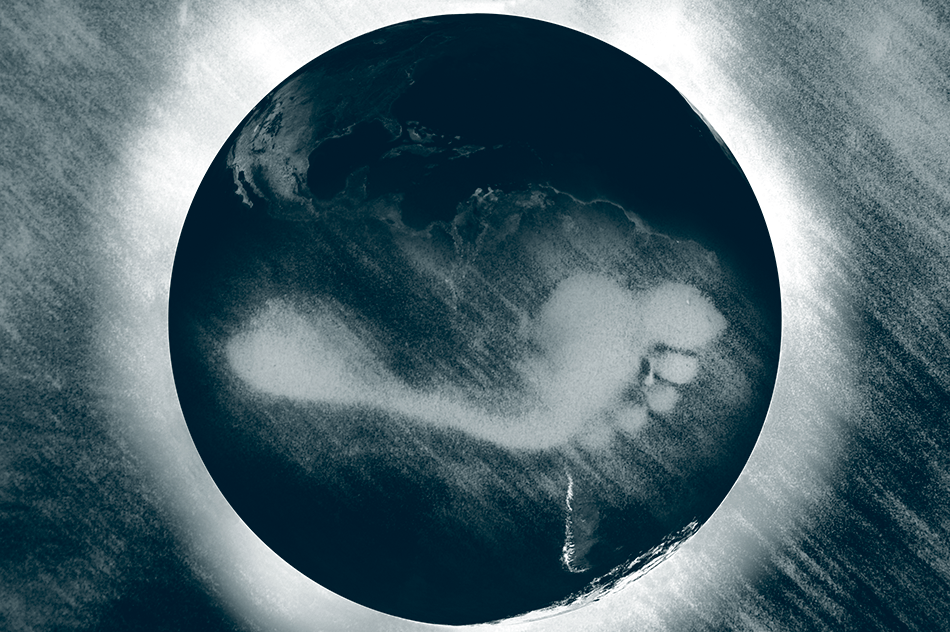

Our style of living determines our carbon footprint; the choices we make and the habits we fall into have a major environmental impact. The ‘we’ I’m referring to here, in terms of trade, concerns conglomerates, small businesses, departments and divisions, right down to the individual who, through daily activities, has a negative effect on our climate.

Even in an average household (moving away from our business focus for a minute), this footprint can be attributed to indirect sources, such as the fuel needed to produce goods far away from the end consumer. As you can see, moving away from the direct impact of commerce we, in fact, end up right back where we started: the carbon footprint of a company.

The time to act is now.

There are numerous ways, I’m sure, in which a company could potentially decrease its carbon footprint but this article aims to explore just one: PLM. How might a PLM solution help to decrease your company’s carbon footprint?

The following comprises just a few suggestions on how we at WhichPLM believe PLM solutions can assist in helping to decrease the carbon footprint of our industry; how PLM can further aid retailers, footwear companies and brands:

Many of the world’s leading retailers and brands are constantly requesting thousands, and in some cases even millions, of samples per year to support their product design and development activities. Recently, I overheard a senior executive from a sports company quoting a requirement of 3 million samples for their European business that, in a lot of cases, are airfreighted from their suppliers back to their European headquarters. Think of the environmental consequence there.

Today’s 3D companies offer a broad range of solutions that have the capabilities to create a diverse range of products: Apparel, Accessories & Footwear etc. 3D solutions are able to create virtual samples that are almost impossible to distinguish from actual products. By introducing 3D virtual sampling into a business and really utilising it, companies could eliminate a fairly large percentage of their physical sample requirements.

3D technologies allow the business users to use 2D patterns from the majority of CAD/CAM systems available that can export DXF standard file formats of the 2D patterns. Several of the 3D solutions today offer high definition, detailed photo realistic images, enabling the suppliers to fully appreciate the concise detailed requirements of the finished products. Furthermore through the software’s collaboration engines the vendor is able to query the requirements online, via collaborative white boards and screen sharing, to ensure that they have all the details to enable each party to deliver the correct finished article, thus reducing the need for multiple sample iterations.

Another area to consider is that of physical fabric samples. Assuming you have decided upon the silhouette to be used, the next step is to obtain the physical fabric sample from sourcing partners. Or is it? Let’s consider an alternative approach: that of digital printing on fabric substrates.

The process takes the digital fabric image, taken from a CAD system based on a 1:1 ratio or repeat pattern and is then printed using a reactive dye based inkjet printer, that can print the image directly onto the fabric substrate. The end result is a 1×1 metre sample length that can then be turned into physical garment samples; the process can be completed in a matter of hours reducing the need for physical samples to be flown in from global sourcing locations. The net result is that physical samples can be produced in a matter of hours as opposed to a minimum of a week/weeks (not to mention the potential of several flights along the way)!

The bottom line is: not only are we reducing the carbon footprint using a digital fabric printing process, but we are also reducing the time of design and sampling by a factor of potentially 25:1, resulting in online up-to-the-minute trend!

Colour management is another key area that can really affect a company’s carbon footprint. Typically it takes at least two to three physical colour samples, which need to be flown into the headquarters, to complete the colour approval process before arriving at the approved finished colour sample. This can result in thousands, if not millions, of samples per year per company, dependent upon the size of the organisation. To save on our footprint, the colour management process can be converted into an online self-digital colour approvals process linked back to the originators colour management system.

It’s all about joining the dots! There is a lot of talk around collaboration today but the fact is that most people see collaboration as a one-way stream leading directly to their vendor and manufacturers! In fact, this is only a very small part of the total solution. In order to help reduce the overall carbon footprint, we really need to consider the extended supply chain including raw material suppliers for fabrics, linings, and components such as buttons, threads, labels, and zippers. All of this can be digitised to enable the early sampling process via images rather than physical samples, resulting in fewer deliveries via road, sea or air, thus helping to reduce the overall carbon footprint and at the same time resulting in a more efficient process, leading to an increase in the overall time to market.

In essence, what this means is that we all need to consider ways of joining the digital dots across every part of the supply chain, from concept through to the finished product delivery, in order to decrease the carbon footprint of your company.

This blog covers some key ways in which a PLM solution might help to decrease your company’s carbon footprint and, as part of your corporate social responsibility, this should be a top priority for any business.