This week, I spent some time talking to Alon Moshe and Alon Bar Shany, CEO and Chairman of Twine Solutions – a pioneering business in the field of digital thread and yarn dyeing. Beyond the benefits to sustainability, speed, and creativity of replacing traditional dyeing methods with digital solutions, I wanted to understand whether this potentially revolutionary technology is ready for prime-time adoption, and I wanted to know what ambitions its founders have for taking it further into production and beyond.

The full recording of our conversation is captured in this exclusive video interview, with a transcript beneath it if you prefer to read:

The transcript that follows has been edited for clarity and length, omitting introductions and some questions, and also reflects some additional conversations that were not captured in the video.

Mark Harrop: I can see a lot of parallels that can be drawn on what is happening today within fashion technology, and what you, Alon Bar Shany, and the team achieved during your time at HP Indigo, which pioneering digital printing. Can you shed a little extra light on those similarities between what happened there and what’s likely to happen in the fashion sector?

Alon Bar Shany: First of all, both textiles and printing are massive industries – among the largest in the world. Printing, when I joined, was a very comfortable industry that had been working for decades in an analogue manner, and many people didn’t even feel there was a need for a change. In that sense, Indigo successfully anticipated some of the macro trends of the internet, and sustainability, and distributed printing – and that contributed to a vision for disrupting the industry by introducing not just digital technology but different business models.

At the core of what we did at Indigo was a privileged technology that scaled and improved in terms of productivity, media range colour gamut, and application fit. But beyond this was a culture of focus on customers, a passion to drive innovation and growth, and over the years experience, in how to scale our customers and our business. By 2020 Indigo was a small, but critical part of the total print business, certainly the most profitable for customers. In fact few customers today in printing do not have a digital footprint, and many are only digital.

The textile industry is also massive, it’s amazing, it’s efficient, it’s global, but when you look beneath the surface there’s definitely a similar need for change. With Twine I see the same potential to disrupt, to enable new applications, and to replace traditional supply chains with much more efficient, robust, distributed, digital supply chains. Digital dyeing has the same potential to power new business models, and also to start dealing with some of the fundamental environmental issues that the current way of working creates.

I see Twine now as being where Indigo was a few decades ago, with massive potential that’s going to take time to realise. We’re going to need to work with customers, the fashion industry, and the end consumer to reach a good balance between traditional ways of working and the new digital way that I think Twine is going to create.

Mark Harrop: Like you said, the consumer is part of this conversation – especially when it comes to the environment and sustainability. There’s a steep, growing curve of concern coming from the conscious consumer, which is driving NGOs that are in turn demanding changes to regulations and tools for enforcement. In fact one of the reasons I’ve been talking to the team from Twine for so long is that vision for zero waste and other mission-critical metrics. How do you see Twine helping to support sustainability?

Alon Moshe: This is certainly one of the biggest subjects in textiles today, and the industry has been discussing it at incredible length. We hear about regulations, circular economy, CSG, recycling, and many other phrases, and it’s all becoming part of the industry’s lingo.

It’s also part of Twine’s core values, and it’s inherent in everything we do. In terms of the system, there are four primary sustainability impact indicators where dyeing digital can make a positive contribution.

The first is environmental hazards created by traditional, wasteful dyeing. On average maybe 30-40% of water used in dyeing is recycled, but what happens to the rest? There’s an enormous amount of fresh water required to dye the thread that ultimately goes into any garment or material, and the majority of it is wasted.

The second is the carbon footprint of packaging, logistics, and supply chain – everything that transports the dyed thread from the dye houses to the manufacturers.

The third is that thread is a low commodity item. The minimum order quantity for a dye house to economically justify production is far out of scale with how much of the thread will actually be used – the proportion of production as applied to the sellable item. And of course the fourth one is downstream: how many garments are ultimately sold, and what happens to those that are not sold?

Jack Ma is quoted as saying that “in the past, it would be impressive if an assembly line can produce 2,000 of the same garments in five minutes. Today onwards, making 2,000 different garments in five minutes will be more impressive,” but what cost does this scale and variety come with?

All of these sustainability challenges are enormous in scale, and we know that the textile industry is one of the largest polluting industries. Placing Twine systems at the manufacturing floors, in design departments, and in R&D addresses all four.

It’s important also to remember that economic justifications are going to be an important driver towards sustainability, but the industry also needs to transcend that, and that’s why we see sustainability as one of the most important elements of what we do at Twine.

Mark Harrop: There isn’t a day goes by where I’m not introduced to new technology that’s being advertised as revolutionary, and ready to change the world. Sometimes, though, we cut through the marketing spin and find either a lack of industry knowledge or discover that the technology’s potential isn’t mature enough. How ready is digital dyeing for wide deployment? And if the technology is ready, then what are the obstacles standing in the way of digital dyeing becoming the new norm?

Alon Moshe: Breakthrough technologies obviously do take time to mature. But the industry is ripe for it; we talk about microfactories, we talk about nearshoring, and the online fashion industry has overtaken the electronic goods space. These are all parts of the megatrends that are combining to create a clear shift away from cost alone, and towards increasing the net production margins and enabling a level of local production that makes economic sense. So Twine manifests well both in the supply chain and in production. Far beyond spin, or “nice to haves,” these are pure musts – and the textile industry is in dire need for change, since it hasn’t changed in a century or more.

As we saw in the printing industry, when digital printing was introduced, those who do not adopt new technology, or who are fearful of moving forward, will find themselves at an impasse.

In terms of obstacles, Twine is like any new technology. The adoption, the scale, both of those will come with time and with further evidence that the technology does what it says it will do, and further awareness of the immense benefits it offers from both an economic and an ecological standpoint. Ultimately there’s no question of whether this will happen. It must happen. And it has been happening already: we’re seeing products going out into the market using thread that was digitally dyed.

Alon Bar Shany: Revolutions take time. Production today, as it’s been done for centuries, has been very optimised; when you do things the same way for decades you get very good at that. And therefore it’s up to us to meet the criteria of the industry. People are not going to compromise. That takes work and time, and it’s not enough to just show results in a lab – you need to demonstrate that you’re a vendor that can scale, and provide a service that delivers clear benefits.

One thing became evident in printing was that digital should not replace everything that was analogue, because the analogue is optimised for certain things. If Twine can capture 5% of the market share of the textile industry, but that 5% is the least efficient and the least sustainable part of this value system, then that’s massive. With Indigo we identified niche applications in different segments, we met the quality needs, and we scaled – and in the process we created totally new industries.

What Twine is doing is certainly not marketing hype, but it’s a long journey, and it’s one we intend to take step by step, working with our visionary customers. The current way of doing things does not make sense long term, and it’s something that our fragile planet can’t sustain. So change is coming, is that’s change that Twine intends to lead.

Mark Harrop: We’ve talked about the benefits to the environment and dramatic improvements to sustainability, but what about the question of business efficiency, speed, and doing more for less? I know it’s early days for you within the Twine business, but are you able to share any initial insights into the extended value chain benefits?

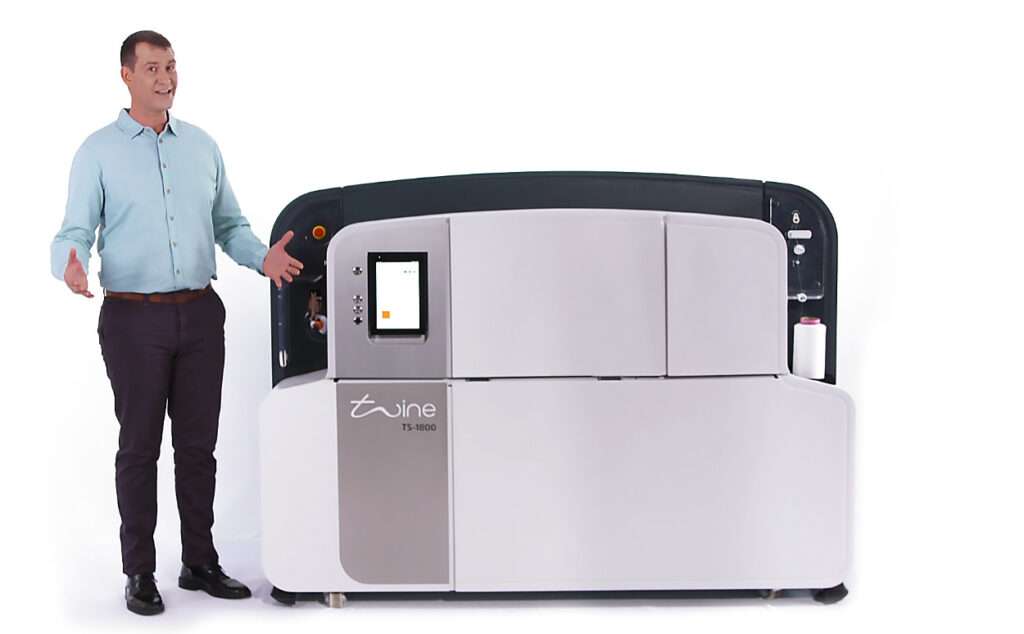

Alon Moshe: The TS 1800 caters primarily to Sales Sample & R&D production but also to low/volume high color mix and premium applications production.

You mentioned efficiency and speed: manufacturers and brands alike now have the flexibility and ease to jump-start the critical design process – from virtual design to the actual build-up of the sample production – in order to identify and approve which products are going to enter the market. Digitally dyeing yarn on-demand with no waste is pretty much unprecedented in the product development stage, so suddenly the efficiency and the speed are there. Gone is that iterative process that it takes to reach the approval stage, and now you can measure the process in days rather than weeks or months. And of course it’s well established that the longer lead times you have, the more chance there is of delays in time to market, price markdowns and so on.

From that point of view, efficiency and speed are critical elements of the first phases. In addition, SKU numbers are on the rise, batch order sizes are reducing, and one of the primary virtues of going digital is having the capability to produce down to the unit level. Manufacturers have never had the ability to produce at that level before, because there was no economic justification for doing so. So you have a situation where material costs, MOQs, and time to market are all less than optimal under the traditional approach, and you couple that with the exponential rise in sustainability vulnerabilities. Twine’s solution provides significant efficiency benefits by improving inventory turnover, and by enabling the value chain to produce only what is needed ultimately to sell.

Mark Harrop: We’ve seen an evolution of business models and technology deployments in fashion technology: from point solutions to platforms, from on-premise to cloud. How do you see the hardware and software that makes up the Twine solution being rolled out?

Alon Bar Shany: At the core of Twine is a privileged technology which enables you to dye thread digitally, with the right colour, which is not easy. But the final business model is a lot beyond that, and it’s one that has an uncanny similarity to printing. Because the aim is to provide a combination of hardware, software, and service capabilities, and everything is cloud connected, you start really disrupting the way things are done beyond the immediate application – into processes like digital colour management, and across continents.

That model also incorporates partners and the workflows they serve and the extended, digital ecosystems we can create together – which will lead to new business models. And the good news is that all of this is far more advanced than you would expect from the outside. Twine is in a position top enable our customers to offer their brands the same products with faster time to market, less waste, and a reduced impact on the environment. But at the same time we will enable them also to build new business models, maintaining consistency and quality while also catering to local tastes and building a more flexible supply chain. From those points of view, I see Twine as a key enabler for the digital future.

Alon Moshe: The ecosystem is an exciting subject, because it brings to the fore our vision and our mission for Industry 4.0 (or Textile 4.0), connecting digital technologies. We also have a DNA and a culture that has its roots in the digital printing industry, and that’s what so exciting: we’re bringing a lot of that experience and understanding to the fashion industry, and using it as a toolkit to allow us to understand out customers’ needs and how their workflows are connected.

For example, the sampling process, once approved, requires a challenging conversion, incorporating colour metamerism and other variables. We have joined forces in our development with COATS, our strategic partner and investor, to envisage what the future of that digital to analogue conversion looks like. And we are also actively engaged in developing a seamless process to allow virtual designs to drive our dyeing system, for integrated, on-demand sampling and production.

So we definitely do not see Twine as a standalone solution. The ecosystem that we, our partners, and our valued customers are building will run end to end.

Additional interview questions are captured in the video recording.

About our partner: Twine Solutions has developed a digital thread dyeing technology that dyes white polyester thread in any colour and on-demand, ready for immediate use, for sewing, knitting and embroidery. The dyeing process is waterless and sustainable.